Extrusion of rubber profiles

One of the flagship products of the Forflon™ brand is Teflon conveyor belts used in hot air vulcanisation and UHF tunnels by manufacturers such as Gerlach, TSM, Cim-Dor, Colmec, and MK Maschinenbau GmbH.

To meet our customers’ expectations and needs, our Teflon™ conveyor belts used in extrusion are made in standard, reinforced, and endless versions.

We offer free consignment storage and just-in-time delivery as part of the standard package.

PROPERTIES

- Increased temperature resistance (up to 340 C)

- Increased tear strength

- Compatible with Gerlach, TSM, Cim-Dor, and Colmec machines

- Choice of versions: Standard, Reinforced, Endless

WHAT MAKES US STAND OUT

Shipping within 24 hours of order

3-stage quality control at every stage of production

Origin of all base materials we use for the production of Teflon belts

Delivery to anywhere in Europe within 72h

Fixed stocks of base materials exclusively for producing belts for the automotive industry

Well-equipped laboratory to work on innovative solutions for demanding applications

Materials

| TYPE | COLOUR | THICKNESS | WEIGHT | COVERAGE | RESISTANCE |

| 250E | Blue | 0,25mm | 534g/m2 | 61% | 2500 N/5cm |

| 250S | Brown/black | 0,23mm | 480g/m2 | 58% | 2200 N/5cm |

| 350SB | Brown/black | 0,35mm | 735g/m2 | 60% | 4000 N/5cm |

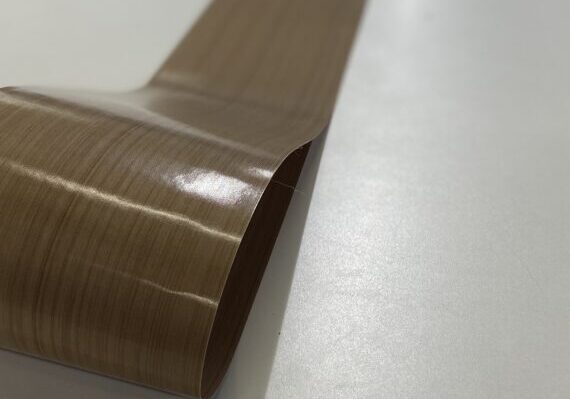

| 4400 | Bronze | 1,00mm | 460g/m2 | 32% | 2200 N/5cm |

250E - Material with an additional coating, characterised by increased durability of the Teflon layer and better non-stick properties

250S - an economical product line combining affordability with good high-temperature properties

350S - A line of materials dedicated to tunnels requiring the use of belts with increased breaking strength while maintaining high anti-stick properties

4400 - Teflon mesh screen with very high air permeability and heat dissipation