Tortilla production

Forflon™ is a leading European manufacturer of Teflon™ belts used in tortilla presses. Our Teflon belts are compatible with all models from manufacturers such as Lawrence, Casa Herrera, and JC Ford.

Innovation

We continuously strive to improve our manufacturing processes and products in our pursuit of perfection.

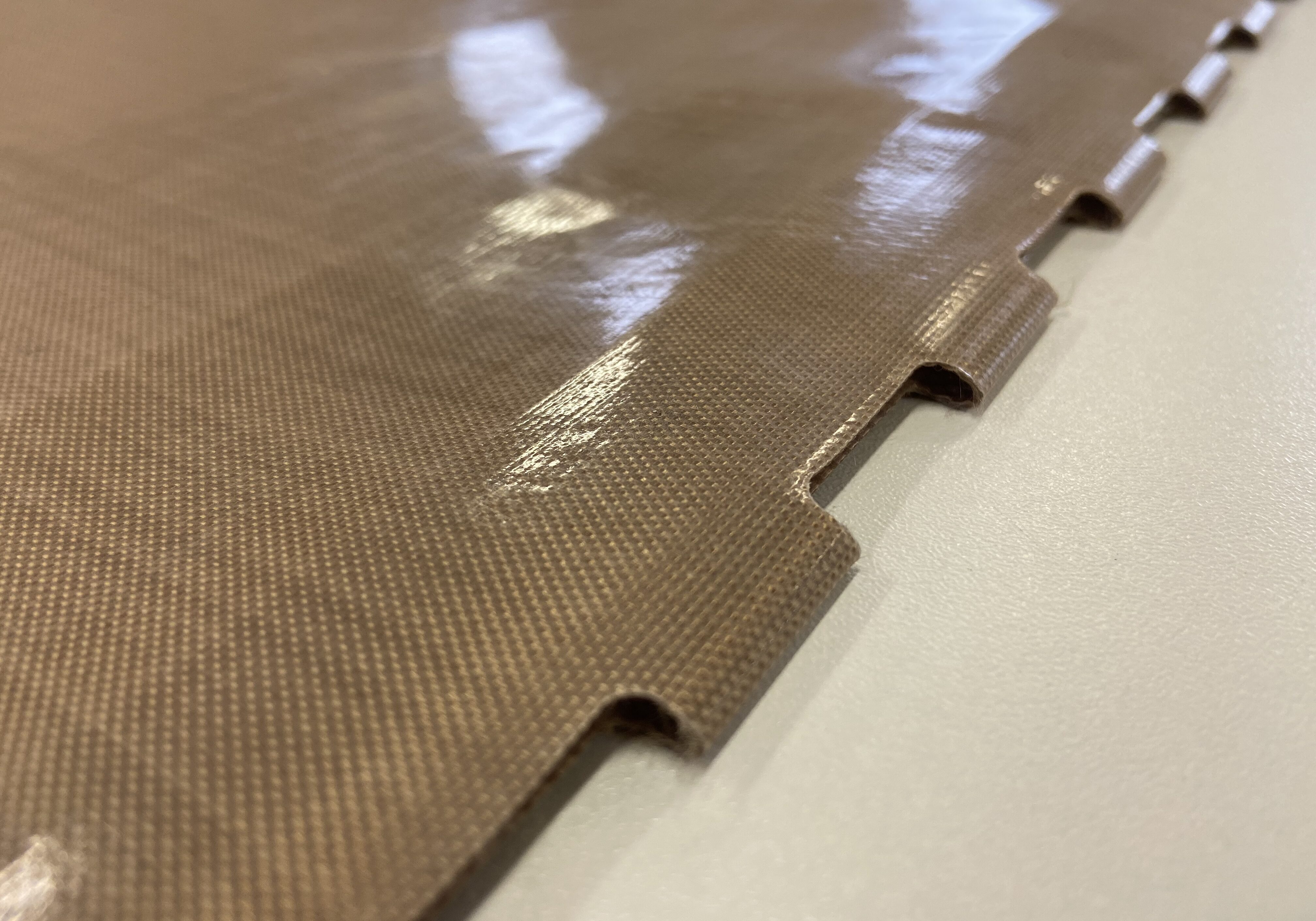

Thanks to numerous tests and trials, we have been able to design a Kevlar® material for the reinforcement of Castellated joints, which at the same thickness shows an approx. 40% increase in strength compared to traditional Kevlar®.

This is very important because, in the case of Teflon conveyor belts in the food industry, the connector is often the weakest link of the whole belt. The Castellated connector we developed is not only perfectly smooth with no visible ridges but is also much more durable than its competition.

WHAT MAKES US STAND OUT

Shipping within 24 hours of order

3-stage quality control at every stage of production

Origin of all base materials we use for the production of Teflon belts

Delivery to anywhere in Europe within 72h

fixed stocks of base materials exclusively for producing food industry belts

42% increased joint breaking strength

Materials

| TYPE | COLOUR | THICKNESS | WEIGHT | COVERAGE | WIDTH |

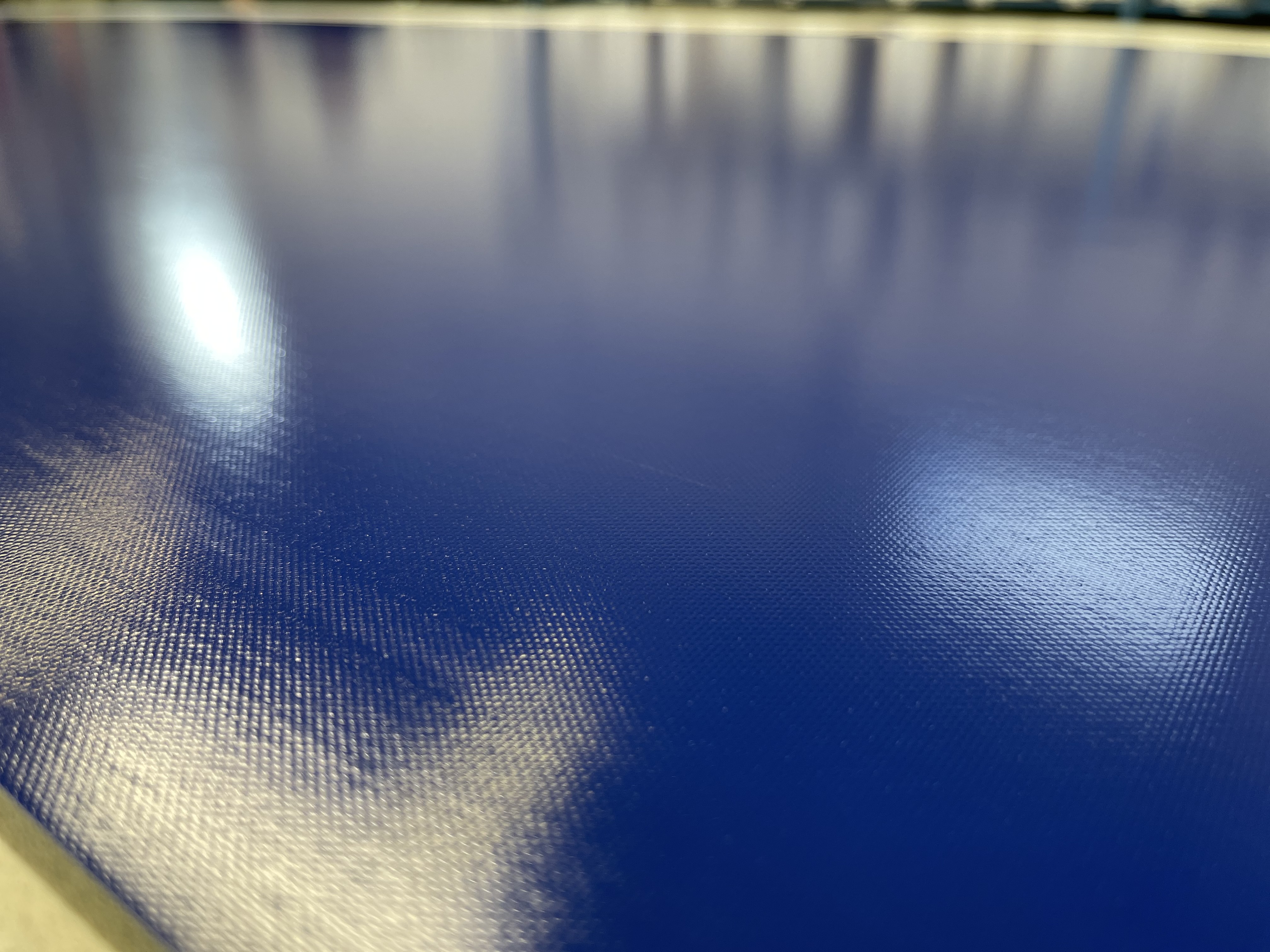

| 250E | Blue | 0,25mm | 534g/m2 | 61% | 1520mm |

| 250S | Brown/Black | 0,23mm | 480g/m2 | 58% | 1070mm |

| 190PLY | Red/Natural | 0,19mm | 380g/m2 | 70% | 1200mm |

| 230GC | Olive | 0,23mm | 460g/m2 | 58% | 1520mm |

250E - A material specially made for the food industry with increased resistance to temperature and grease burns

190PLY - FORLAM™ 190PLY is a material with a 2PLY structure characterised by increased stability during operation under challenging conditions. Due to its excellent heat conductivity, the use of this material allows for shorter production cycles

250S - an economical product line combining affordability with good high-temperature properties

230GC - our specially designed material with the addition of copper. The fabric has excellent heat conductivity and increased abrasion resistance